Intellix BMT 330 – Bushing Monitoring and Partial Discharge Detection for Transformers

GE’s Intellix™ BMT 330 is an on-line system that continuously monitors the condition of the bushings and can also detect developing partial discharge (PD) activity in the transformer main tank. It will alert personnel of fault conditions at an early stage and provide vital health information on the bushings and the transformer.

The Intellix BMT 330 can be utilized as a standalone system to monitor bushing insulation and partial discharge activity, or as an integrated, one-vendor solution with GE’s Kelman DGA 900 Dissolved Gas Analysis (DGA) multigas analyzer and PerceptionTM Fleet software providing a more in-depth view of the transformer’s condition and root cause of major transformer failures.

Key Benefits

- Comprehensive monitoring of transformer bushings and PD activity on a 3 phase transformer or a bank of 3 single phase transformers

- One product combining on-line continuous bushing monitoring and partial discharge activity in the transformer main tank using the same bushing adaptor

- One diagnostic software, GE’s Perception, used for bushing information, PD activity and DGA data analysis, resulting in familiar easy-to-use information

- One supplier installing, servicing, ensuring proper communication and minimizing administrative burden in order to lower the total cost of ownership of your transformer

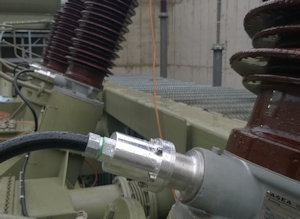

The Intellix BMT 330 Bushing Solution

The Intellix BMT 330 continuously monitors the condition of bushings in real-time and provides end users with the information they are used to receiving from off-line tests, namely changes in capacitance and power factor (tan delta), to assess the bushing dielectric efficiency and insulation integrity.

Intellix BMT 330 with Kelman DGA 900

The Intellix BMT 330 can easily be integrated with GE’s Kelman DGA 900 analyzer, giving the end user a unique all-in-one solution that provides a more comprehensive view of the transformer’s overall condition, from bushing diagnostics and PD, to complete main tank monitoring.

Suomi

Suomi Svenska

Svenska