Transformer Monitoring and Diagnostics

Transformer Monitoring and Diagnostics

Need to know condition of transformers in electricity networks is increasing when transformers are ageing. Up to date and accurate monitoring data is needed in particular from large and critical transformers. Such transformers are usually located in the transmission networks, heavy industry and power generation.

Analysis of a transformer oil sample by a laboratory is an established technique recognised as the most important test for monitoring power transformers. It has long been accepted that Dissolved Gas Analysis (DGA) of oil is the single most powerful tool in the field of transformer fault detection and asset management.

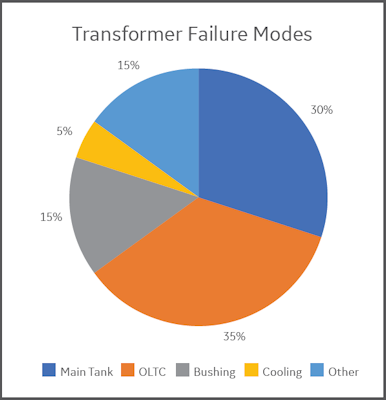

While on-line DGA is now widely accepted as the most effective method of assessing the condition of a transformer, it does not cover all the possible sources of issues. Sub-systems like the tap changer, the cooling system or the bushings can generate their own problems if they are left unmonitored.

GE Vernova’s line of Kelman and Hydran products, now has a comprehensive offering of portable, on-line products and software for management of critical transformer assets. With these products transformer faults can be detected in early stage minimizing risks for costly unplanned outages and equipment failures.

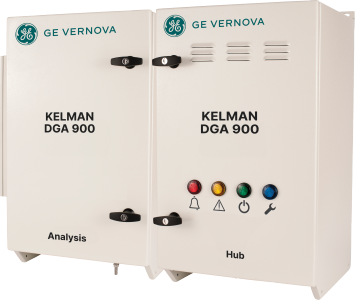

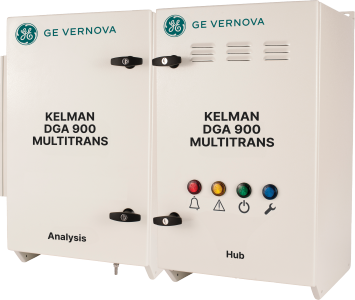

Multigas online DGA for transformers

GE Vernova’s multiple gas DGA products consists of Kelman products, which are based on advanced Photo Acoustic Technology (Photo-Acoustic Spectroscopy). The key benefit of this technology is ability to measure levels of each fault gas separately and accurately.

Photo Acoustic Technology does not require calibration of the system or using carrier or calibration gases. This gives remarkable benefits and savings on operating and maintaining these units.

Kelman Transport X2

Compact portable system that is designed for laboratory quality Dissolved Gas Analysis (DGA) on manually taken samples from transformers filled with mineral oil and ester fluids. It allows fast diagnostics in less than 30 mins through an improved graphical touchscreen user interface.

Perception Fleet

GE Vernova’s Perception Fleet is a smart, simplified and standards-based software system that moves customers from a manual, one-on-one transformer assessment process to an automated and online fleet management assessment. By automatically evaluating the condition of assets and establishing their risk of failure, Perception Fleet is able to prioritize and rank assets within a fleet.

The Perception Fleet software provides customers comprehensive transformer fleet condition rankings, transformer risk information, and expert analysis on-demand, removing time-consuming and costly manual processes as well as unnecessary maintenance, helping focus capital and reduce operational expenses.

Suomi

Suomi Svenska

Svenska